How to Choose the Right Stretch Film Gauge

Stretch film is a critical part of a packaging process that has a direct impact on product safety & integrity.

Without the right film for your load, you risk damage to products and injury to employees. But the stretch film gauge you choose also has a surprisingly large impact on profitability and sustainability.

Given the large volume of stretch film required for sufficient load containment, companies are always looking for ways to trim film expenses.

Some might think they have to sacrifice productivity or quality to reduce costs. But there doesn’t always have to be a trade-off. It’s possible to cut costs, contribute to sustainability, and accelerate throughput.

But only if you assess your packaging operation holistically. By looking at the big picture, you can discover better packaging solutions that support your business goals.

Read on to learn how to “rite-gauge” your stretch film.

When to Down-Gauge Your Stretch Film

Do more with less. That’s the promise of down-gauging.

To down gauge a stretch film means switching to a product that has a slightly thinner thickness, but with similar load containment properties as the wrap currently in use. Thinner films require less material. By reducing materials, you also reduce costs and increase profits.

It can – if you choose a low-quality, low gauge stretch wrap that doesn’t meet the requirements of your load.

We see this all the time. We’ve worked with customers that have cut corners to save a little bit of money on film only to introduce larger issues with packaging quality.

The key is to find the right low-gauge stretch film.

New innovations in polymers and additives make it possible to achieve superior load containment, clarity, and ease of application at lower gauges than previously possible.

At Crown Packaging, we partner with leading stretch film manufacturers to give our customers access to the latest innovations and the best films available.

There are many stretch film products available and it can be confusing, so consider us a resource to help you explore your options.

When to Upgrade Your Stretch Wrap

The common advice when it comes to stretch film is “thinner is better.”

The idea is that by reducing the thickness or gauge of the film you can reduce costs. This is true in many situations, but not always.

For example, we met with a customer who is a big manufacturer of consumer goods, during the site visit, we took a look at their stretch wrap process.

The operations manager was bragging about how he has uses the thinnest stretch film. “I got 39 gauge film,” he said. “Nobody’s in my industry uses thinner film in than me.”

As we’re watching the stretch wrapper going up and down, wrapping the product multiple times, he goes on to say, “I just wish I could speed the process up a little bit.”

“You absolutely can,” I said. “Why don’t you go to an 80 gauge film. Go thicker so you just have to run the film up and down once.”

For this particular customer, going up in size was the right move. By upgrading his film we were able to help increase the quantity of products shipped.

We were also able to help them reduce costs and support their sustainability goals.

Why? Because we were able to provide a better packaging solution while reducing the amount of materials used overall.

Compare Films using a Cut and Weigh Test

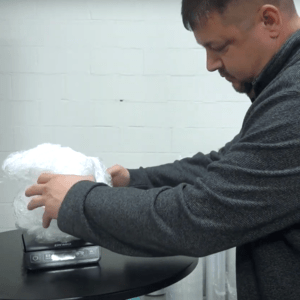

Because the concept of upgrading to a thicker, more expensive film is somewhat counter-intuitive when the objective is to reduce costs, we like to do a “cut and weigh test” to illustrate how this is possible.

Because the thicker film requires fewer revolutions around the load, it involves less material.

This is an easy way to see the material reduction and understand how upgrading your film can sometimes be the right solution to help reduce costs and your company’s carbon footprint.

Take a look at at rite-gauging analysis in action in this video:

Choosing a Sustainable Stretch Film

Some organizations may explore changing their stretch film as part of their green initiatives. There is good news for organizations with sustainability goals when it comes to stretch wrap.

New high-performance eco-friendly stretch films are entering the market that allow companies to go green while maintaining high efficiency, product safety, and load containment.

Stretch films that enable you to reduce plastic use are only part of our portfolio of sustainable packaging solutions.

Improve your Stretch Film Strategy

Which approach is right for your business? Find out by talking with a Crown Packaging Representative.

We’re here to help assess your business’s packaging needs and support you in finding the best solution. Contact Crown to get started today.

More Packaging Articles

Packaging Solutions to Prevent Product Damage

Learn about packaging solutions to help prevent product damage, spoilage, theft, sun exposure, and more.

Six Qualities to Look for in a Packaging Supplier

Choosing the right packaging supplier is important to your operations and your bottom line. Here are six things to look for when selecting a packaging partner.

Hidden Costs of Poor Packaging Supply Management

Running out of packaging materials can be frustrating for employees at best. But failure to have supplies on hand can even impact your organizations’ bottom line.