Contacts

Crown Packaging | Subject Matter Experts

Supplier Contacts

Product Basics

Stretch wrapping equipment is designed to efficiently provide optimal load containment by mechanically pre-stretching stretch film anywhere from 200% – 400%, far more than anyone could do by hand. Stretch wrapping equipment can also create significant improvements in material cost, efficiency, safety, and product protection. Stretch wrappers can be semi-automatic, fully automatic, or a hybrid of both. Knowing the right questions to ask will help you determine which stretch wrapper is right for your customer’s application.

Types & STyles

There are a wide variety of stretch wrapping machines available. Get to know the different types and why each one might be preferable for a customer.

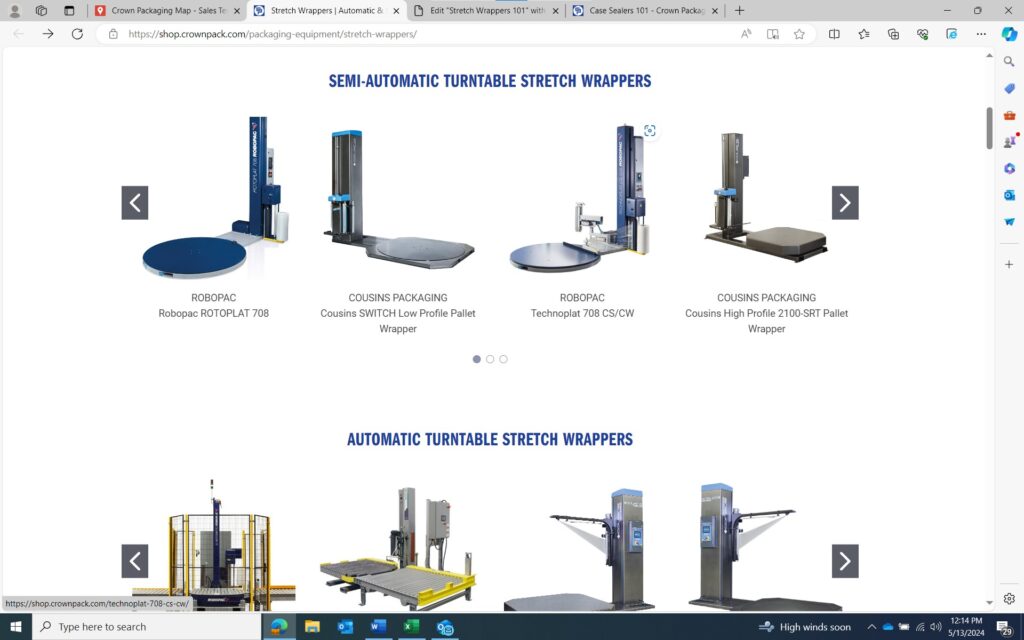

Turntable Wrappers

The turntable style is one of the most popular types of stretch wrappers. Pallets are loaded on a turntable that rotates as the film carriage moves up and down. Turntable wrappers are well suited for many applications and environments.

Rotary Arm Wrappers

On a rotary arm stretch wrapper the load stays stationary while the film carriage rotates around it, wrapping the load as it rotates. Rotary arm wrappers are useful for “B” or “C” loads, unstable, or heavy loads. Rotary arm wrappers are typically faster than turntable wrappers because the carriage arm can rotate faster than a turntable can safely rotate a load.

Ring wrappers

Ring Wrappers are the fastest stretch wrappers on the market today. With a ring wrapper the film carriage is mounted to a large ring that rotates at high speed as it travels vertically around a stationary load. Ring wrappers are used primarily in the beverage industry and building products industry.

Orbital Wrappers

Also known as horizontal ringer wrappers, orbital stretch wrapping machines wrap a load over and under while the pallets move on a conveyor system. You’ll often find orbital wrappers being used in situations with irregularly shaped or flattened loads, like hardwood flooring or textile rolls.

key Attributes

Semi-Automatic Vs. Automatic

Semi-Automatic Stretch Wrappers: As the name implies, semi-automatic stretch wrappers require partial control from an operator who positions the load and secures the film to the load before starting the wrapping cycle. Consider using a semi-automatic stretch wrapper for low-volume applications.

Example of Semi-Automatic Stretch Wrapper

Fully Automatic: Automatic stretch wrappers, by comparison, can wrap pallets with little to no involvement from an operator offering a higher level of effeciency. Pallets are delivered via conveyance systems and positioned to be wrapped. Many automatic stretch wrappers can determine the height of the load to optimize the wrapping process and ensure maximum load containment. Automatc stretch wrappers are well-suited for high-volume production environments.

Example of Automatic Stretch Wrapper

Important Components & Concepts

Stretch Wrapping vs. Hand Wrapping

Stretch wrapping equipment is designed to eliminate the need for manual hand wrapping which has to be performed by an employee.

The benefits to efficiency, safety, and product protection are significant.

In addition to delivering a much faster wrapping solutions, stretch wrappers provide a more consistent wrap, often results in better load containment.

As stretch wrappers require less intervention from staff, this type of packaging equipment is important to support workplace safety.